Aluminum laser cutting Minifaber

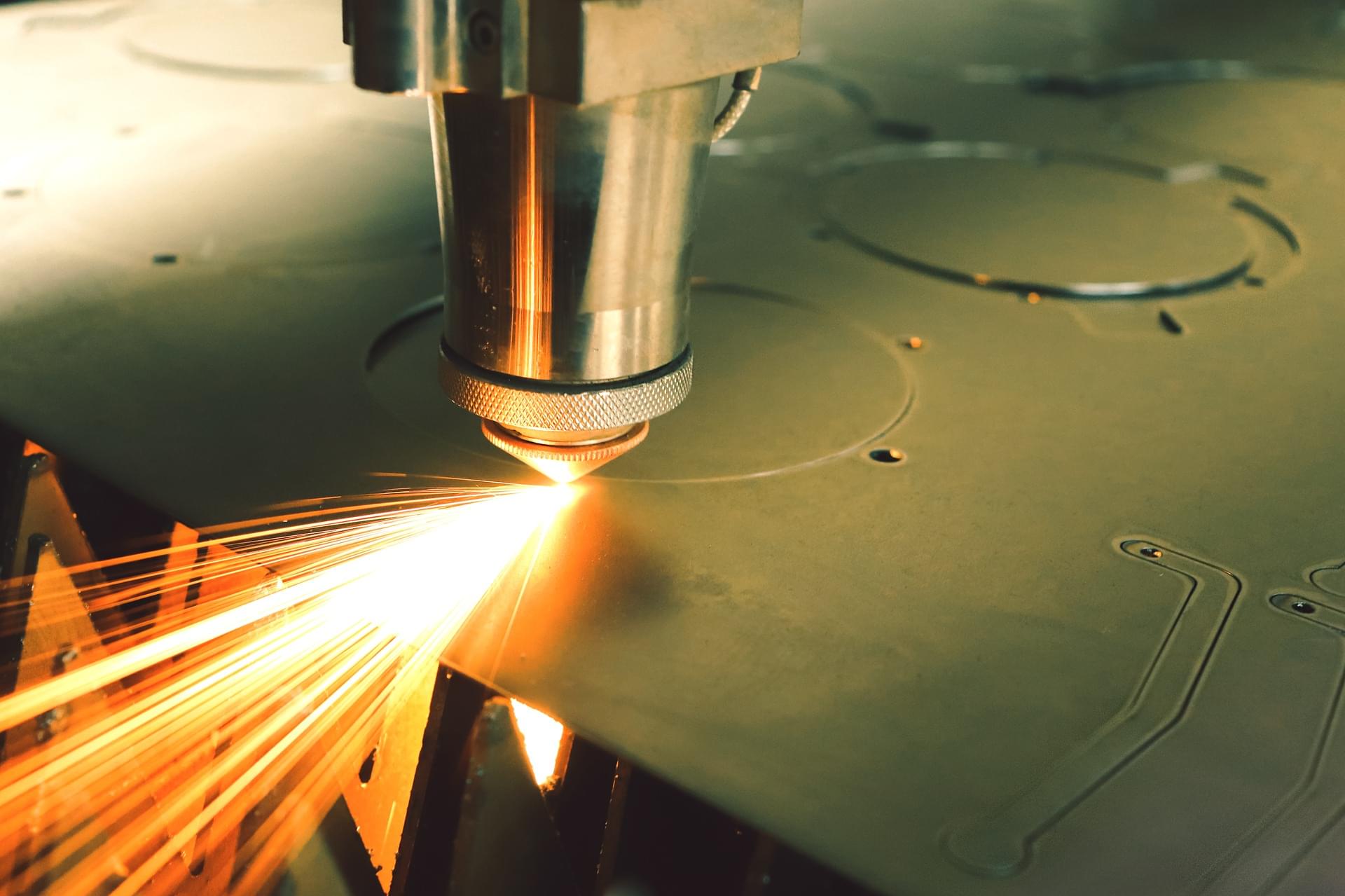

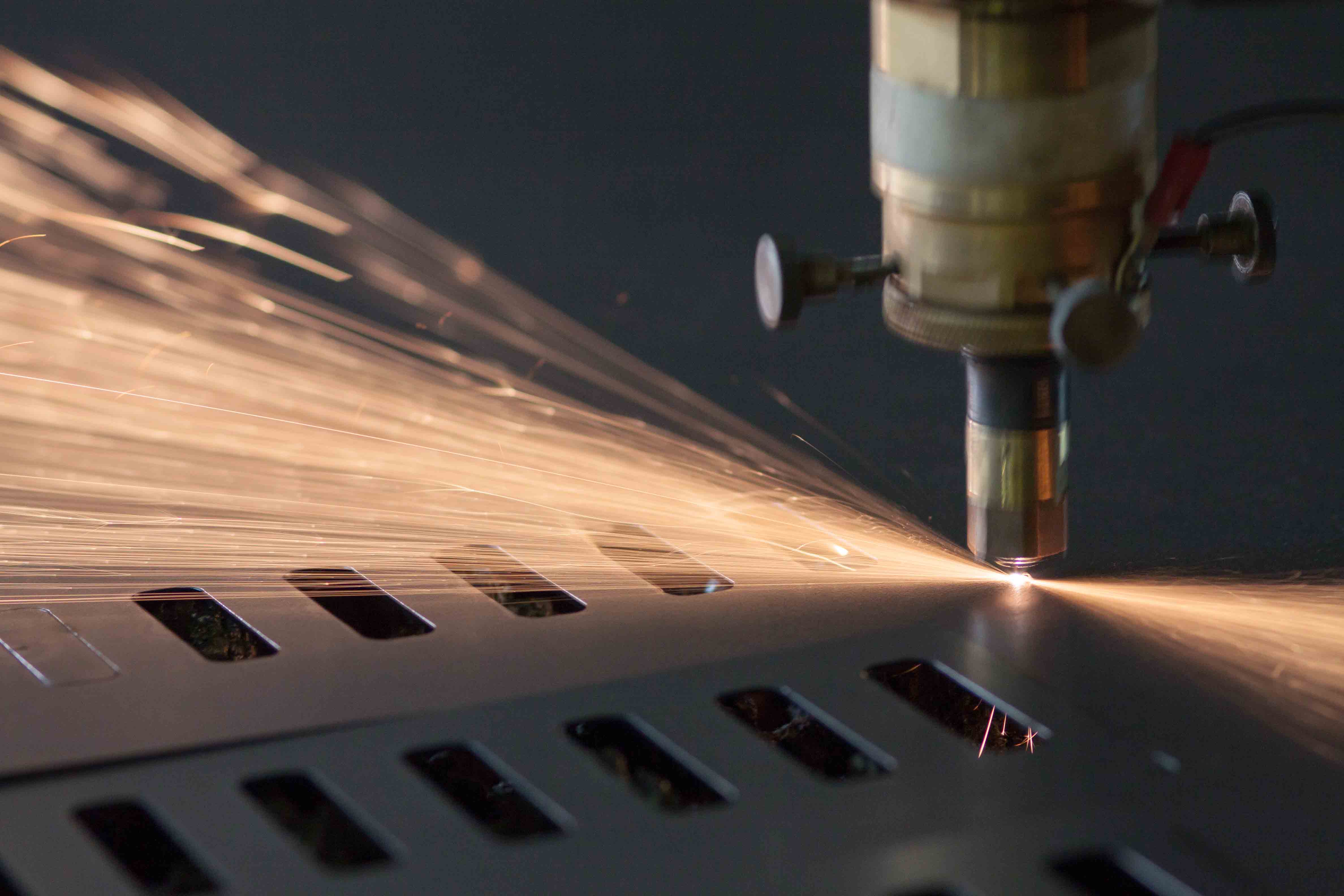

Laser cutting aluminum is a manufacturing process that uses a high-powered and tightly focused laser beam. This is to precisely cut aluminum sheets or plates to exactly match CAD-specified shapes or patterns. It is a critically important method for metal fabrication, offering major advantages over more traditional cutting techniques.

Outdoor Decorative Aluminum Laser Cut Panels Laser Cut Metal Screens Weathering Steel Screens

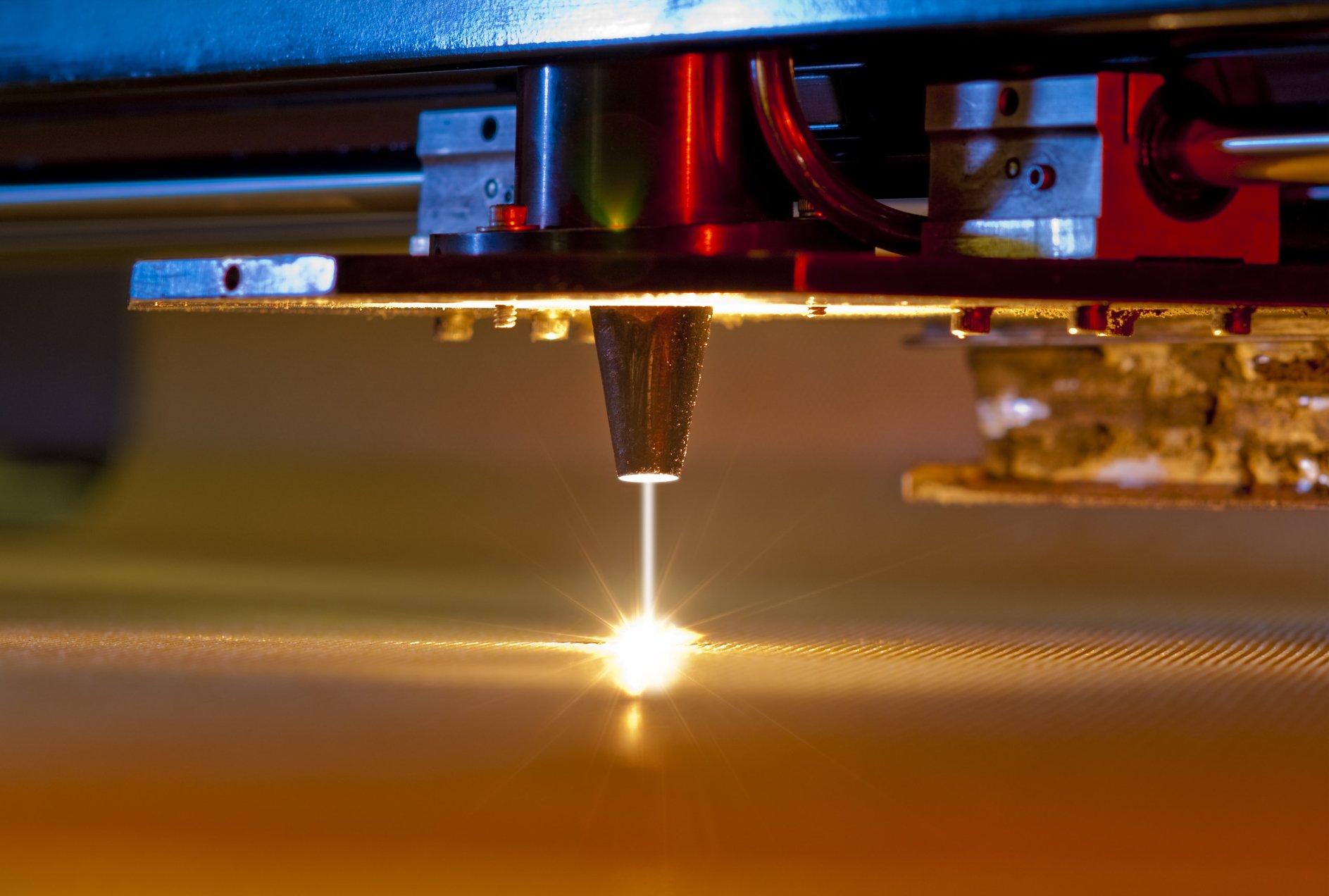

Cutting aluminum with a CO 2 laser is of course quite common. But the CO 2 's 10.6-micron wavelength still isn't ideal, so the process remains a little like squeezing a small round peg in a larger square hole. It's not impossible; the peg still fits through the hole, but securing it takes some effort.

Laser Cutting Aluminium

Eric Johnson December 3, 2020 Aluminum is one of the more challenging materials to laser cut. That's not to say it can't be done, but it does require a bit of expertise. Among other things, it can be difficult to create a clean-cut edge when laser processing aluminum.

FEDERAL METAL WORKS

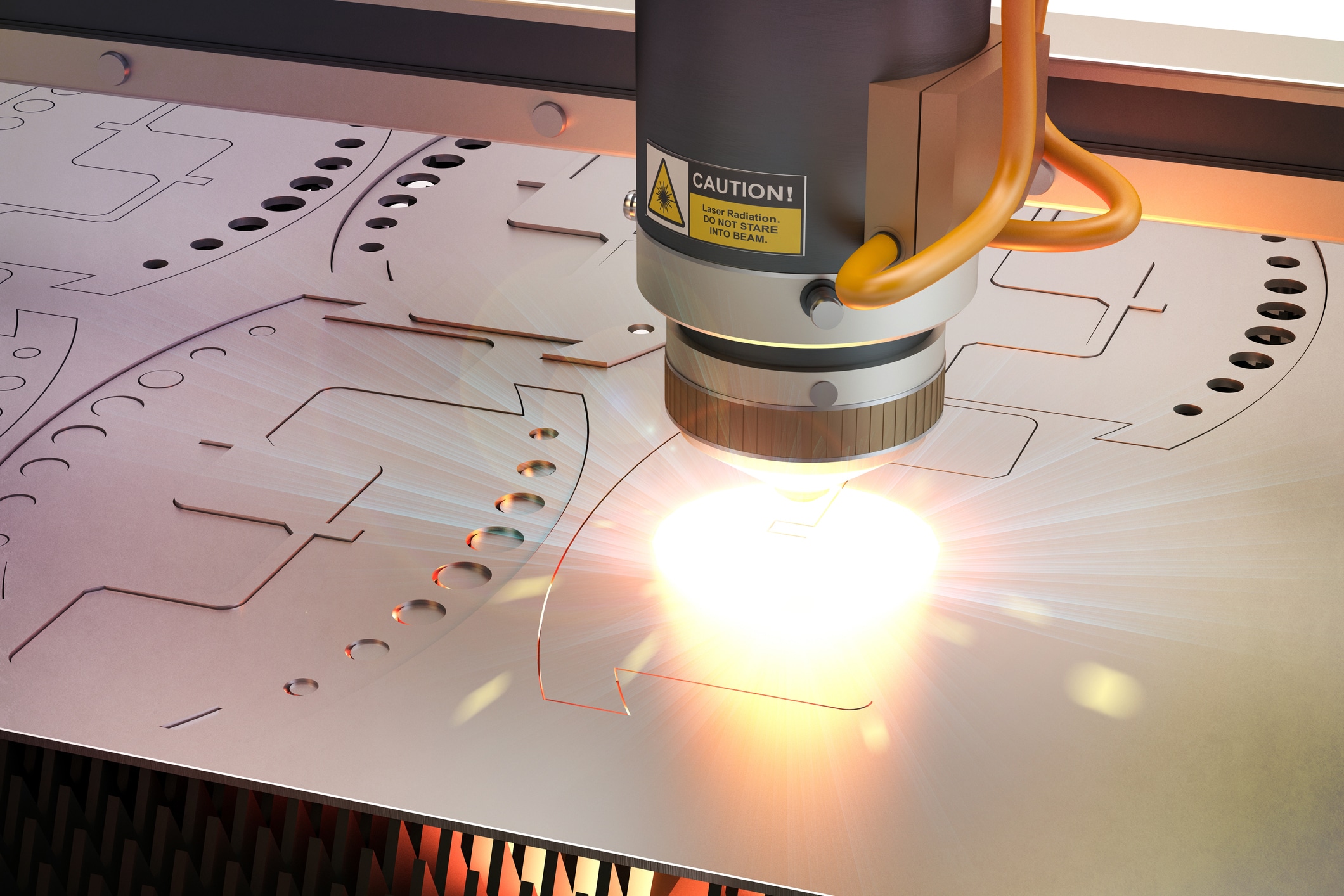

Laser Cutting Steel and Aluminum December 13, 2023 Although metal cutting operations traditionally employ mechanical or manual processes, laser cutting can be a viable, effective, and cost-efficient option for metal fabrication. Laser equipment is distinct from other cutting machines in both design and application.

Laser Cut Waive Aluminum Railing & Privacy Panel Laser Cut Arts CanadaUSA

For aluminum around 1mm thick, a typical cutting speed may be between 1 and 2 meters per minute (m/min). For 2mm thick aluminum, the speed may drop to around 0.5 to 1 m/min. But bear in mind, going too slow can cause excessive heat buildup, while too fast a speed may result in incomplete cuts.

Laser Cut Metallic Paint Aluminum Screen Panels/ Mashrabiya Partition/ Room Divider China Wall

We support custom metal cutting in various alloys of steel, stainless, aluminum, copper, brass, bronze, and nickel. No Minimums We are happy to handle your custom metal cutting and bending orders of any size, from a single prototype to a production run with thousands of metal parts.

6 Advantages of Laser Cutting

Laser Cutters Can Be Used to Cut Aluminum Plate In recent years, advancements in laser technology have led to increased evaluation of the benefits of laser cutting aluminum. The laser cutting process allows for faster processing of consistent parts, making it more efficient than traditional methods.

Laser Cutting Portland Custom Metal Cutter Services Near You in WA Naimor Inc.

A fiber laser with a power rating of around 30W with a frequency of 25kHz - 50kHz and a cutting speed of 4.3 inches/sec (210mm/s) is recommended for laser engraving aluminum. Generally, the engraving output on aluminum is light gray with less contrast to the actual color of the metal.

Decorative Laser Cut Aluminum Panels Bexterior Wall Covering 1000x2000mm

Online laser cutting services made easy Upload your CAD file We accept DXF, EPS, DWG, AI, STP & STEP and files. Get an instant quote Prices include materials, cutting, deburring and free shipping anywhere in the USA, $19 to Canada Standard orders out the door in 2-4 days or less 1-3 day shipping on all standard orders No CAD File? No Problem!

metal Aluminum laser cut panel for facade privacy screen fence with 2mm thickness metal

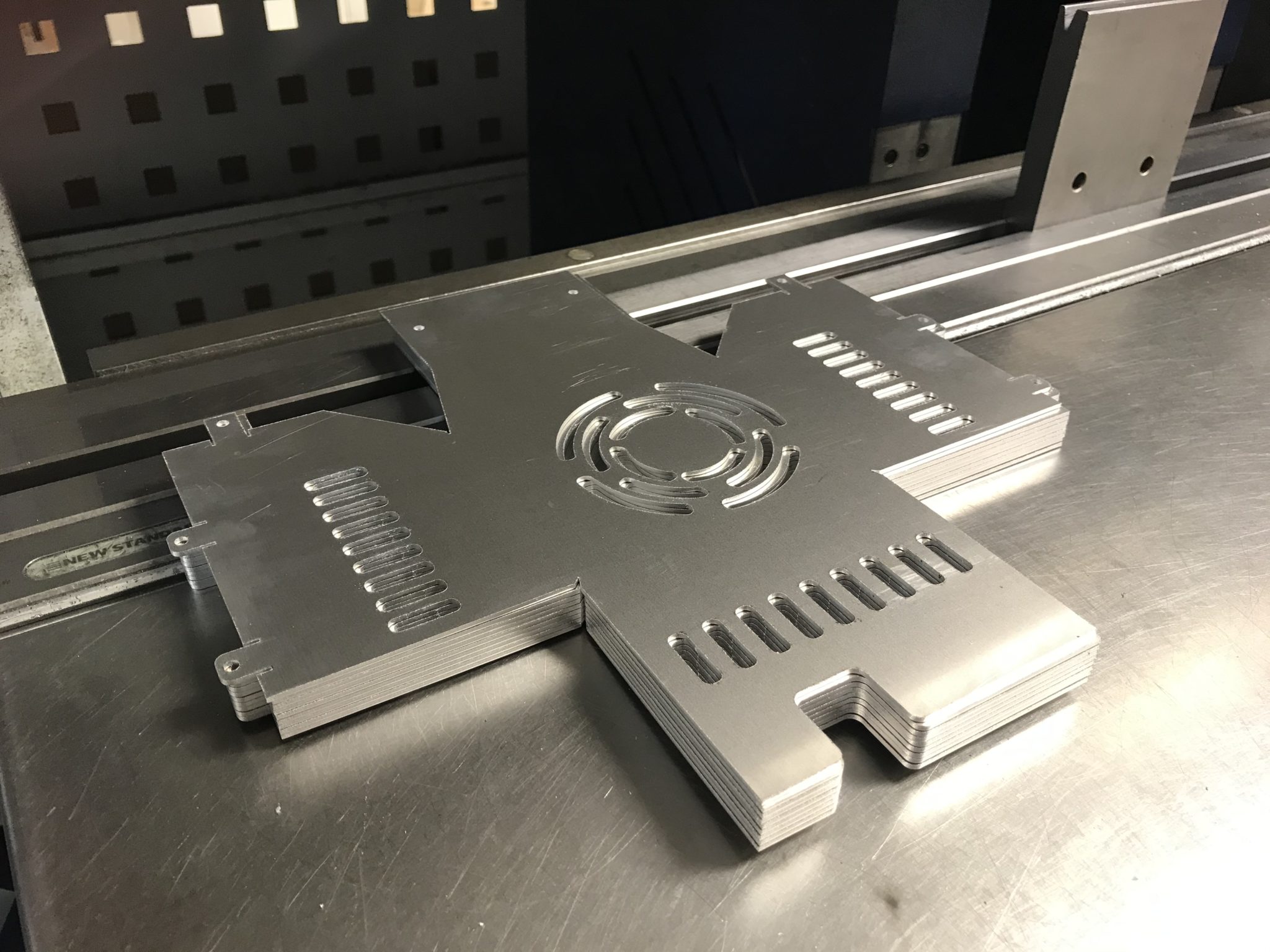

Laser cutting aluminium is the right choice until thicknesses up to 6…8 mm. From there, the quality suffers noticeably and the material needs extra machining. We would not advise laser cutting past 20 mm. When going past 8 mm, water jet is the suitable cutting technology. Combining speed, quality and a cheaper hourly rate makes water jet.

Custom Laser Cut 5052 Aluminum

Create custom sheet metal parts in a variety of materials and your choice of finishing. Get an instant quote for sheet metal fabricated parts, such as enclosures or brackets.

Facade Laser Cut Aluminum Panels , Perforated Pattern Sheet Metal Laser Cutting

5052 series laser cut aluminum is one of our most popular metals. Used in a wide variety of applications including aerospace, automotive and robotics, our 5052 aluminum is an excellent mix of high performance and affordability. Available thicknesses range from .040″ - .500″. Laser cut sheet metal (+/- .005″ cutting tolerance)

Aluminum Material for Laser Cutting

What is Laser Cutting Aluminum? Laser cutting is a state-of-the-art manufacturing technique that employs a high-powered laser beam to meticulously slice through aluminum sheets or plates. At its core, the process harnesses the intense energy of the laser, focusing it on a specific point on the aluminum surface.

AluminumLaser Cutting Beacon Engineering Works

Laser cut 2024 T3 Aluminum is one of the strongest materials we offer here at SendCutSend. With unmatched tensile strength, 2024 T3 Aluminum is the best alloy for projects that require the highest structural integrity and robustness. Available in .025″ thickness. Laser cut sheet metal (+/- .005″ cutting tolerance)

Laser Cut Aluminum and Laser Cut Steel A Guide

The simple answer is yes. You can cut aluminum with CO2 laser cutter or fiber lasers machines. This blog post will cover the best laser-cutting techniques and tips for aluminum. It will also include the best thickness aluminum for successful cuts according to the cutter machines. Contents show How to Laser Cut Aluminum?

Laser cut decorative metal screen aluminum material 2mm thickenss 1m x 2m

Contact Us Laser Cutting Company offers aluminum laser cutting and forming services for aluminum parts to the OEM and replacement part markets. We serve a wide range of industries, including the automotive, aerospace, heavy equipment, military, agricultural, medical, and power generation industries